Turnaround & Capital

intelliSPEC’s™ Digital Turnaround & Capital Project Management delivers transparency through management dashboards and digital wall charts to provide real-time visibility to enable managers to make intelligent and informed decisions faster so the turnaround stays on schedule and on budget. The Digital Turnaround Manager offers the ability to import P6 schedules directly into intelliSPEC™ and export reports back to P6 or other sources such as Excel, Word, PDF, etc.

intelliSPEC’s™ Digital Turnaround & Capital Project Management offers true digital connection to unify the worker in the field with company management for operational excellence through:

Digital Wall Charts

Task Management

Transparency of Work

Real-time Capture of Field Work

Critical Path Monitoring

Weld Tracking

Critical Flange Tracking

PRV & MOV

Digital Permitting

Vendor Surveillance

Blind Tracking

Mobile Inspection & Management

Digital Job Safety Analysis

Automated Productivity Information

KPI Dashboards

intelliSPEC™ Can Assess Your Turnaround Readiness

intelliSPEC’S™ Digital Turnaround & Capital Project Management is more than just optimizing processes and providing real-time optics on the activities that take place during a turnaround, intelliSPEC™ provides the only Digital Turnaround Assessment tool.

The Turnaround Assessment solution helps aid in the turnaround planning process to ensure an on budget and on schedule execution.

This process takes place over a span of 24 months before the turnaround takes place and includes several readiness reviews, scope assessments to monitor development and a post turnaround review to identify lessons learned to improve future efforts.

Turnaround Flange Management

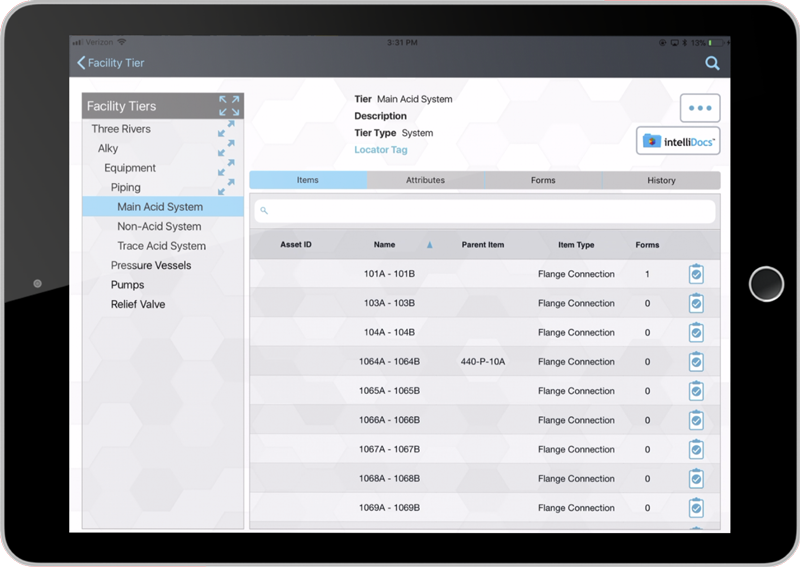

The intelliSPEC™ Flange management solution can be used for multiple turnaround and maintenance outages while quickly allowing stakeholders digital access to historical data. This streamlines the process, allowing your team to build work packs for the next outage.

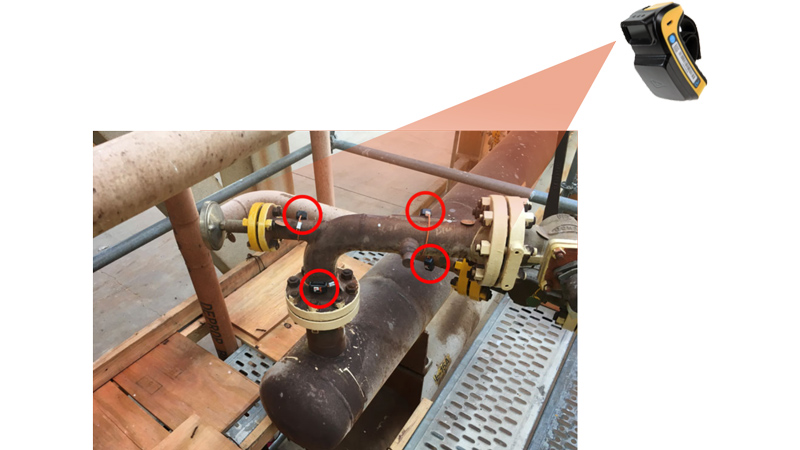

Utilizing the intelliSPEC™ platform with SmartTag RFID technology provides increased efficiency and accuracy in reporting during preplanning, turnaround and maintenance work.

intelliSPEC’s™ Flange Management Solution is proven to reduce the flange management process by 42% vs. traditional paper tag methods. Only the intelliSPEC™ platform can provide standardization and transparency by:

Optimizing the task of tracking critical flange connections. HF Alky, Hydrogen, etc.

Providing confidence that flange faces are in a condition to ensure no product leakage

Assuring flange connections have been reassembled in the correct manner

Providing a critical flange database

Identifying critical flanges as an asset in a CMMS

Provide RFID tagging to easily identify critical flanges and track flange repair history

Track and report status of disassembly, inspection, completion of necessary repair and proper joint reassembly

Track process blinds installed prior to execution of equipment outages

Track removal of process blinds at completion of equipment outages

Turnaround reporting & post turnaround reports

Tags are scanned using the RFID scanner

Data is entered into a mobile device via intelliSPEC™

All collected data can be viewed on the management dashboard